Services

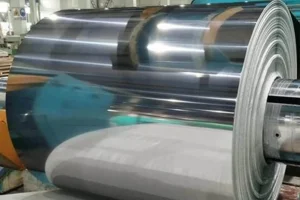

Allied Copper Alloys are a versatile provider of a whole range of precision coil services. Offering a range of grades, thicknesses and tempers in copper, brass, bronze, nickel silver, stainless steel and aluminium. We’re able to slit widths or blank sheet from master coils to meet your requirements. Whether that might be 10kgs or 10,000kgs, one width or multiple, we are able to help. We pride ourselves and listening and working with our customers to make sure we’re supplying a product that meets their needs.

Whatever your rolled metal requirements, our knowledgeable and experienced staff are on hand to supply a quality assured service, competitively priced and personally tailored to your needs

Coil Polishing

- We work closely with third party polishers to get the finish and coil speicifcations required.

- Bright/mirror

- Satin brushed

- Dull

- Grit polish

Polycoating

- A range of protective coatings are available to protect the surface of your coil.

- From low tack to laser coating we offer a range to fit your needs.

Edge Dressing

- Our in-house line allows us to edge dress coil to remove burr to help minimise health and saftey risks and improve material effectiveness.

- Providing manufacturers a cost effective and safe solution.

Electroplating / Hot Dip Tinned

- This process can be applied to copper, brass,

bronze or stainless steel to increase corrosion

resistance and solderability. - Pure tin or a 60/40 tin can be applied.

- Thickness Range: 1-50 microns

Traverse Wound Coil

- Increase productivity and minimise machine downtime

- Thickness Range: 0.25mm – 1.20mm

- Width Range: 10mm – 50mm

- Reel Width: 350mm

- Reel ID: 300mm carboard

- Weight: 500kgs – 1,100kgs